How does a flute work?

Do you want to know how a flute or piccolo is built? Then you've come to the right place. On this page, we discuss all the parts of a flute and their functions.

Are you looking for information about specific keys? Then we recommend checking out our page on keys and trill mechanisms.

What is a flute?

A flute is a straight tube that you play horizontally next to your body. The instrument consists of three parts:

- Head joint – Conical bore; the player blows into/over the embouchure hole to produce sound.

- Body – Cylindrical bore; the largest part of the flute with most of the keys.

- Foot joint – The lower part with a few keys, used to play the lowest notes.

The keys on the flute open and close holes in the tube, each producing a specific tone, either alone or in combination with others.

What is the Head Joint?

The head joint is the part of the flute into which you blow, converting air into sound through vibrations and air splitting. This makes a good head joint incredibly important for a flutist! For young beginners, curved head joints are available. These shorten the overall length of the flute, allowing young children to hold and play the flute in a comfortable and responsible way.

The Lip Plate

The lip plate is the thin, flat piece of material attached near the end of the head joint, where the player rests their lower lip. When air is blown correctly across the embouchure hole, it causes air vibrations inside the flute through air splitting, resulting in sound/tone. The shape and material of the lip plate influence the sound quality and playability of the flute.

The Riser

The riser, or chimney, connects the lip plate to the head joint. It forms the first point of contact between the airflow and the flute, influencing the sound quality.

Adler

Rainer Lafin developed the so-called ‘Adler,’ named after the wings of this bird. The lip plate features two narrow, tapered ‘elevations.’ These ‘wings’ help produce a slightly brighter and deeper sound. Muramatsu also offers head joints with these ‘wings,’ calling them Tsubasa.

The Cork and Crown

The head joint is sealed with a tuning cork. The crown is screwed on top of the cork and forms the visible end of the head joint. The cork itself sits inside the tube. Its position is crucial for the intonation and tuning of the flute. The crown can also be made from different metals.

Metal Head Joints

Just like the body material, head joints can be silver-plated, silver, gold-plated, or gold.

It goes without saying that each material produces a different sound. Precious metals like silver and gold provide an even richer and warmer tone than silver-plated or gold-plated options. Flute and head joint makers freely combine these materials. For example, there are silver-plated head joints with a silver lip plate or riser, which enhances the sound. Major head joint makers like Lafin and Mancke also produce silver head joints with gold lip plates, risers, and crowns. The choices available today are vast!

Wooden Head Joints

In addition to metal head joints, wooden head joints are also available, mainly used on wooden flutes or piccolos. Wooden head joints provide a completely different tonal palette and add a unique warmth to the overall sound of the flute or piccolo. Nowadays, wooden head joints are also used on metal flutes, especially for certain repertoires (such as Baroque music). A well-known wooden head joint maker is Mancke.

The type of wood determines the tonal color and characteristics. Due to its high density and bright, stable sound, the most commonly used wood is grenadilla. Other woods used include cocus, mopane, rosewood, and kingwood.

Types of Wood

Piccolo Head Joints: Reform or Non-Reform?

Reform head joints have a profiled shape around the embouchure hole, providing many players with a more direct response and easier articulation on their piccolo. Reform head joints are also known as profile or wave head joints. Standard or smooth head joints do not have this profiling.

In addition to reform and straight headjoints, there are also models with a lip plate. The player’s preference determines the best choice.

The Body of the Flute

The tube of the flute’s body can be made in two ways: from an existing tube or from a sheet of metal. When the tube is made from a metal sheet, it is called a “seamed tube.” Seamed tube flutes are more expensive because their production is very labor-intensive. Most flutes are traditionally made from an existing tube.

Heavy Wall

This refers to the thickness of the flute’s tube and is also known as a thick-walled flute. A thick-walled tube is usually 0.45 mm (0.018") compared to 0.40 mm (0.016") for nickel silver flutes. A heavy wall provides more resistance, making the flute harder to play. However, it offers a fuller, richer sound and greater control.

What is a Tone Hole?

Tone holes are the openings in the body and foot joint of the flute, onto which the keys are mounted via the mechanism. By opening and closing the keys, you can change the pitch. These tone holes can either be soldered or drawn from the tube.

Drawn Tone Holes

Most flutes have drawn tone holes, meaning they are pulled from the tube rather than being separately soldered on. As a result, these tone holes are slightly thinner. All beginner and step-up flutes have drawn tone holes. You can easily recognize them by the slightly thicker rim at the top of the hole. If you are an advanced player or professional, you can choose between drawn or soldered tone holes. It’s a matter of testing and experimenting to find what suits you best.

Soldered Tone Holes

Soldered tone holes are made separately and then soldered into place. Because soldered tone holes are thicker than drawn ones, they increase the flute’s weight. Players looking for a slightly darker sound and more resistance often choose a soldered tone hole model. Due to the significant time required to hand-solder each tone hole, these models are more expensive. They are typically found on flutes designed for advanced or professional players.

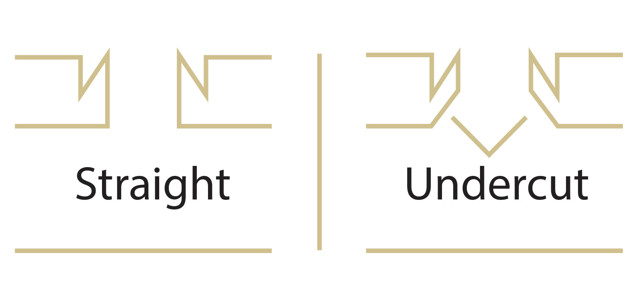

Undercut Tone Holes

This means that where the tone holes meet the tube, they are beveled to allow air to flow through the instrument with less resistance and a clearer tone. It can also result in more precise tuning.

The Mechanism

When talking about the mechanism of a flute, people refer to the keys, rods, arms, and posts. The mechanism is usually considered part of the body.

Key

The keys cover the tone holes. Covering more tone holes lowers the pitch. Keys are attached with an arm to a rod, which is then secured to the flute’s tube with posts.

Open or Closed Keys?

One of the first choices when selecting a flute is whether to have open or closed keys. With open keys, five keys in the middle are open: two for the left hand and three for the right hand. This means you must cover the hole completely with your fingertip; otherwise, the note won’t sound properly. The main advantage is that it encourages more precise finger placement, improving technique. Additionally, flutes with open keys tend to sound more "open" and have less resistance. Their response is often more precise and smoother than flutes with closed keys.

The advantage of closed keys is that these flutes are slightly easier to play at first, especially for children with smaller fingers. However, for flutes with open tone holes, plugs are available to cover the holes. Many flute makers now offer flutes with open keys even for beginners.

Pads

The keys cover the tone holes with pads. These are located under the key and are usually made of felt with a thin covering. Soldered tone holes require different (thinner) pads than drawn tone holes because they have a thin rim, unlike drawn tone holes.

Arm

The arm is the piece that connects the key to the mechanism. It is located in the center of the keys (where your fingers do not rest). Pointed key arms are the traditional key design, combining elegance with strength. In general, pointed key arms are considered a sign of good craftsmanship and durability. Another name for them is "French arms."

C# Trill Key

Many handcrafted flutes for advanced players now come with a C# trill key. This is an extra key located to the left of the index finger key for the right hand. A C# trill key makes certain trills easier (such as C-C# and G3-A3) but also offers additional benefits for intonation and technique.

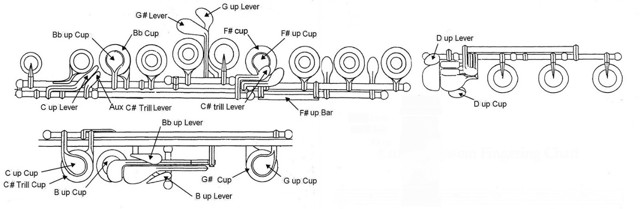

Keys and Trills

The Foot Joint

The foot joint is the rearmost part of a flute and is often considered part of the body.

Just like open-hole keys, beginner flutes are increasingly offered with either a C-foot or B-foot. Compared to years ago, this now makes little difference in price. In the image, you can see a B-foot on top and a C-foot below.

Systems

A system refers to the placement of the tone holes and keys. Flutes only have one type, based on the Böhm mechanism. There are no flutes with a German mechanism. However, different flute makers may add extra keys or slightly adjust key placement. This means many flute brands have their own ergonomics. The Kingma system is an example of this.

Böhm System

Immediately before the development of the Böhm system, flutes were mostly made of wood, with an inverse conical bore and eight small tone holes that could easily be covered with the fingertips.

Böhm’s work was inspired by a flute played by soloist Charles Nicholson. This instrument had larger holes, producing a greater volume than other flutes.

In addition to large holes, Böhm introduced "full venting," meaning all keys remained open. He also aimed to place the tone holes at acoustically optimal positions on the flute’s body rather than where they were easiest for the player to cover.

To achieve this, Böhm designed a system in which the keys were mounted on a rod and connected to rings surrounding other tone holes. This allowed the closing of one hole with a finger to automatically close a second key on another tone hole.

Böhm later discovered that a larger air volume produced a stronger and more defined tone. At that point, he decided to replace the conical bore with a cylindrical one. He also found that an optimal tone was achieved when the tone holes were too large to be covered by the fingertips alone. This led him to develop a system of keys to cover the holes.

These new flutes were initially made of silver, although Böhm later produced wooden versions.

The cylindrical Böhm flute was introduced in 1847, and during the second half of the 19th century, it was gradually adopted by professional and amateur players across Europe and the rest of the world.

Kingma System

Invented and patented by Eva Kingma, a Kingma flute functions the same as a Böhm flute with a C# trill key. All standard keys and fingerings are in their expected places. What makes this flute unique is the addition of six extra keys.

These keys allow for six of the seven quarter tones and multiphonic openings that a standard French flute does not have.

For more information, visit Eva Kingma’s website.

Brögger Mechanism

The Brögger Mechanism is a special system designed by Danish flute maker Johan Brögger. It replaces the traditional pins normally used in flutes.

Instead of traditional pins, the Brögger Mechanism uses a system of bridges and full back connections. This makes the mechanism smoother, quieter, and reduces wear, as there is less friction between moving parts.

In short, this system creates a more precise and durable flute that plays more comfortably and requires less maintenance.